Products Description

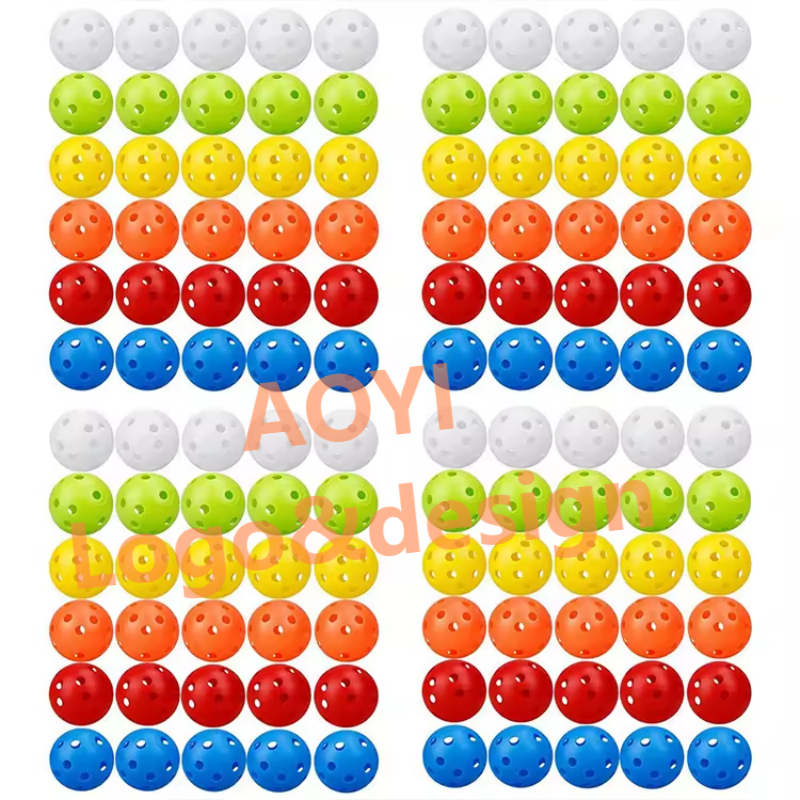

Outdoor Pickleball Balls

Features:

Outdoor pickleball balls typically have 40 smaller holes and are heavier than indoor balls. They are designed for outdoor courts and are well-suited for faster play and powerful shots. The more compact design allows them to better withstand wind, ensuring faster flight and maintaining a stable trajectory in outdoor conditions.

Playing Surface:

Outdoor balls are ideal for harder, rougher surfaces such as concrete, asphalt, or grass courts.

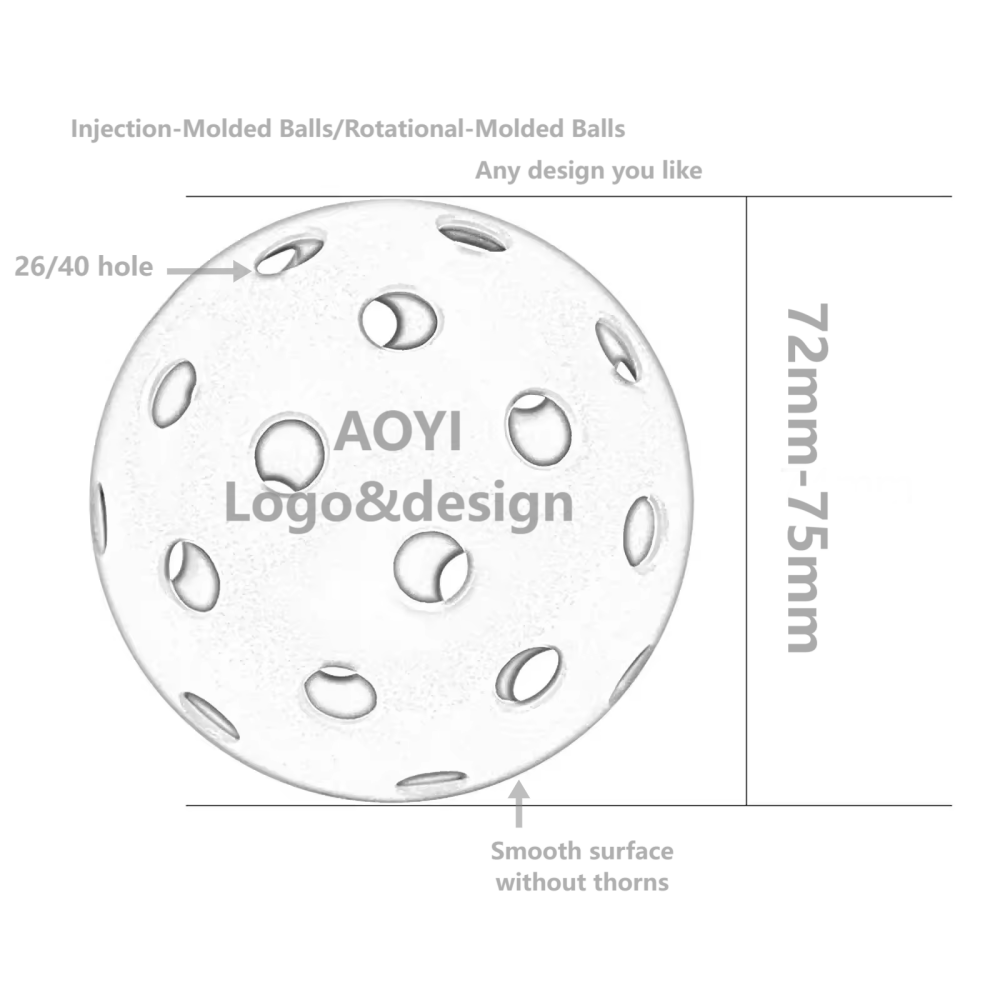

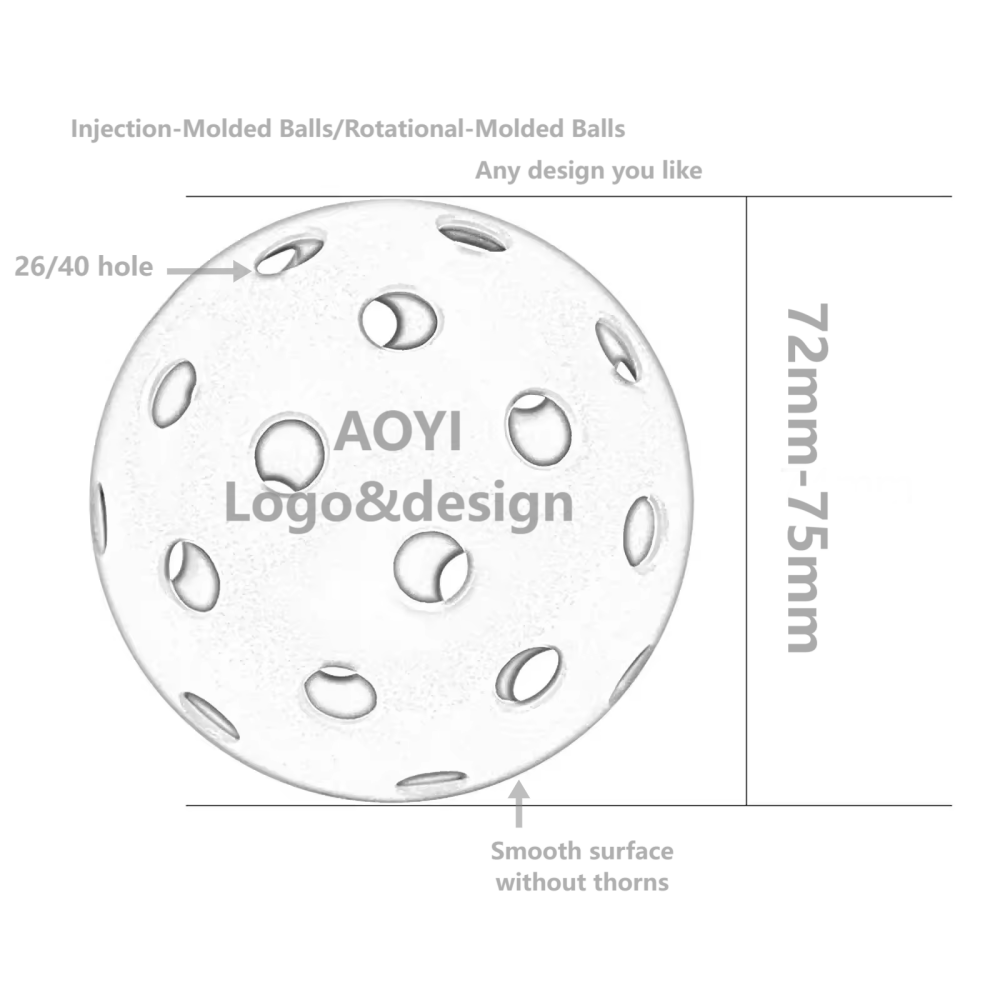

Manufacturing Processes:

- Injection-Molded: These balls are made by fusing two half-shells together through heating, leaving a visible seam in the middle. While injection-molded outdoor balls are more affordable, they tend to have lower durability compared to balls made with the rotational molding process.

- Rotational-Molded: Seamless balls made with this process are stronger, more uniform, and have better abrasion resistance, making them suitable for harsh outdoor conditions. These balls offer superior elasticity and a longer lifespan.

Outdoor Pickleball Balls Details

| Ball Type | Material Description | Key Highlights | Main Advantages | Applicable Scenarios | Technical Specifications |

|---|---|---|---|---|---|

| Outdoor Pickleball Balls | Made of hard plastic for better durability and wind resistance during outdoor play | Smaller holes, harder plastic, faster play |

|

Outdoor courts, competitive play |

|

Tags:

Technical parameter

Outdoor Pickleball Balls 1

Outdoor Pickleball Balls 2

Outdoor Pickleball Balls 3

Outdoor Pickleball Balls 4

Outdoor Pickleball Balls 5

Outdoor Pickleball Balls 6

Outdoor Pickleball Balls 7

Pickleball Ball Manufacturing Processes

1. Injection-Molded Balls

Features:

These balls are made by fusing two half-shells of plastic together through heating, leaving a visible seam in the middle. This method produces balls that are more affordable, making them suitable for beginner players or cost-conscious consumers. However, the presence of a seam makes these balls less durable and less elastic compared to seamless balls. They may wear out faster, especially in high-intensity outdoor environments.

Price: Lower, ideal for players with a limited budget.

2. Rotational-Molded Balls

Features:

These balls are made using a seamless one-piece molding process, resulting in a smooth surface without any visible joints. Balls made with this process are stronger, more durable, and offer more uniform elasticity and consistent performance. They are suitable for high-level play or players who demand premium quality. Seamless balls tend to have a longer lifespan, especially in harsh outdoor conditions.

Price: Higher, suitable for players who prioritize quality and participate in regular competition.

Injection-Molded Pickleball Balls Details

| Ball Type | Material Description | Key Highlights | Main Advantages | Applicable Scenarios | Technical Specifications |

|---|---|---|---|---|---|

| Injection-Molded Pickleball Balls | Constructed using injection molding, providing a high level of durability and precision | Durable, precise, uniform structure |

|

Recreational and competitive pickleball games |

|

Rotational-Molded Pickleball Balls Details

| Ball Type | Material Description | Key Highlights | Main Advantages | Applicable Scenarios | Technical Specifications |

|---|---|---|---|---|---|

| Rotational-Molded Pickleball Balls | Made using rotational molding technology, creating a seamless, durable ball with consistent thickness | Seamless design, uniform weight distribution, high durability |

|

Ideal for both indoor and outdoor use, professional and recreational play |

|