Products Description

Indoor Pickleball Balls

Features:

Indoor pickleball balls typically have 26 larger holes and are lighter in weight. They are designed for indoor courts and are ideal for players who prioritize control over speed. Due to their lighter weight and larger holes, indoor balls have a slower flight and are easier to control, making them suitable for maintaining consistent ball placement in indoor settings.

Playing Surface:

Indoor balls are best suited for smooth indoor surfaces, such as hardwood or synthetic floors.

Manufacturing Processes:

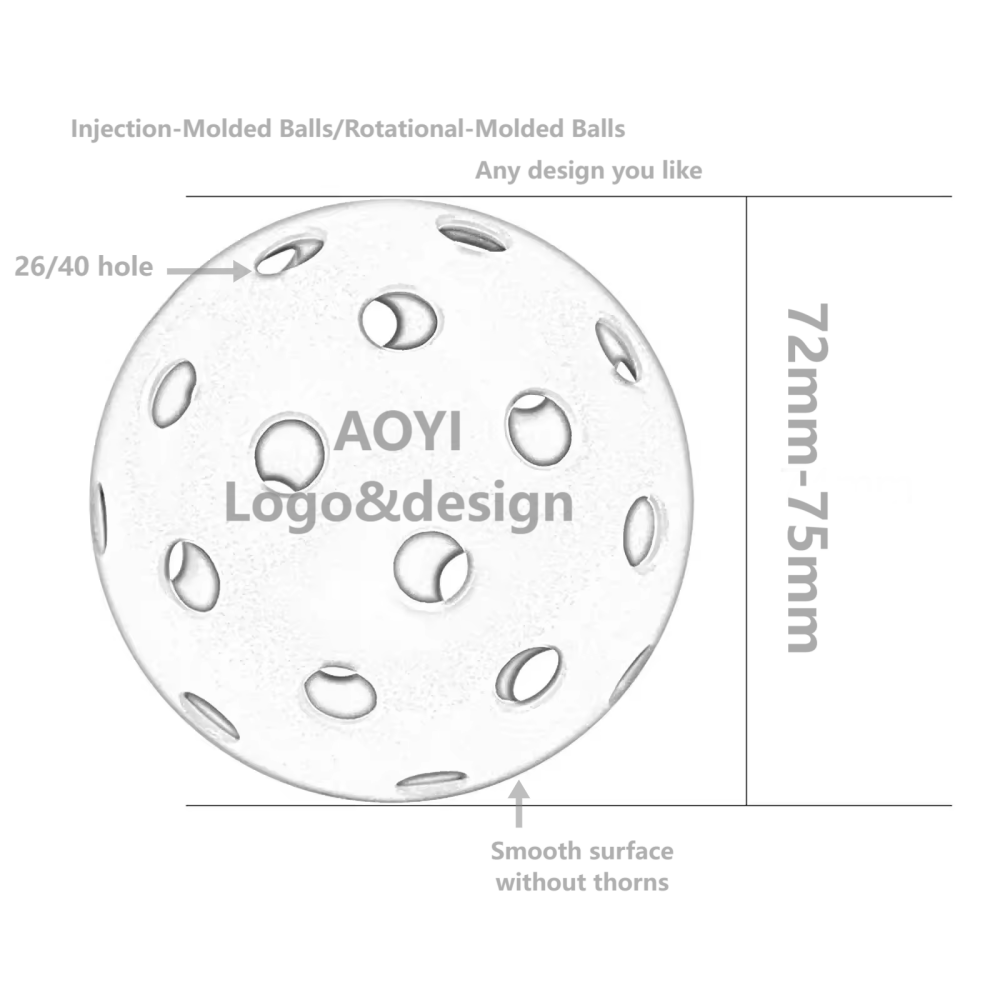

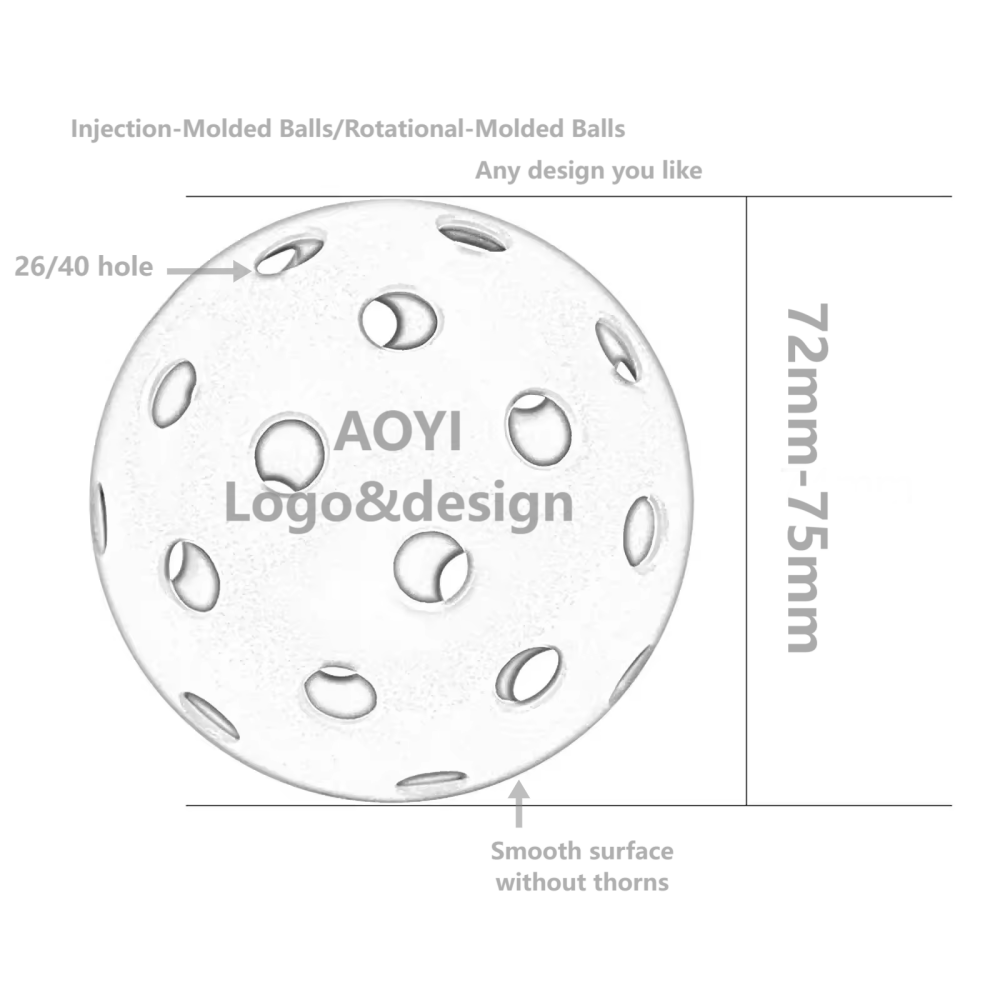

- Injection-Molded: The ball is made by fusing two half-shells together through heating, leaving a visible seam in the middle. These balls are more affordable, but the seam may slightly affect durability and elasticity.

- Rotational-Molded: The ball is made in a seamless one-piece molding process, resulting in a smooth surface and a stronger, more durable structure. These balls have more consistent elasticity and are better suited for players seeking higher quality. Seamless balls are typically more expensive.

Indoor Pickleball Balls Details

| Ball Type | Material Description | Key Highlights | Main Advantages | Applicable Scenarios | Technical Specifications |

|---|---|---|---|---|---|

| Indoor Pickleball Balls | Durable plastic material with smooth surface, designed specifically for indoor play | Larger holes, softer bounce |

|

Indoor courts, recreational and competitive play |

|

Tags:

Technical parameter

Indoor pickleball balls 1

Indoor pickleball balls 2

Indoor pickleball balls 3

Indoor pickleball balls 4

Indoor pickleball balls 5

Indoor pickleball balls 6

Indoor pickleball balls 7

Indoor pickleball balls 8

Pickleball Ball Manufacturing Processes

1. Injection-Molded Balls

Features:

These balls are made by fusing two half-shells of plastic together through heating, leaving a visible seam in the middle. This method produces balls that are more affordable, making them suitable for beginner players or cost-conscious consumers. However, the presence of a seam makes these balls less durable and less elastic compared to seamless balls. They may wear out faster, especially in high-intensity outdoor environments.

Price: Lower, ideal for players with a limited budget.

2. Rotational-Molded Balls

Features:

These balls are made using a seamless one-piece molding process, resulting in a smooth surface without any visible joints. Balls made with this process are stronger, more durable, and offer more uniform elasticity and consistent performance. They are suitable for high-level play or players who demand premium quality. Seamless balls tend to have a longer lifespan, especially in harsh outdoor conditions.

Price: Higher, suitable for players who prioritize quality and participate in regular competition.

Injection-Molded Pickleball Balls Details

| Ball Type | Material Description | Key Highlights | Main Advantages | Applicable Scenarios | Technical Specifications |

|---|---|---|---|---|---|

| Injection-Molded Pickleball Balls | Constructed using injection molding, providing a high level of durability and precision | Durable, precise, uniform structure |

|

Recreational and competitive pickleball games |

|

Rotational-Molded Pickleball Balls Details

| Ball Type | Material Description | Key Highlights | Main Advantages | Applicable Scenarios | Technical Specifications |

|---|---|---|---|---|---|

| Rotational-Molded Pickleball Balls | Made using rotational molding technology, creating a seamless, durable ball with consistent thickness | Seamless design, uniform weight distribution, high durability |

|

Ideal for both indoor and outdoor use, professional and recreational play |

|